Before any further conjecture, rumination, and obsession regarding this candy, the recipe:

Method 1 — Ideal Tahini Conditions Met

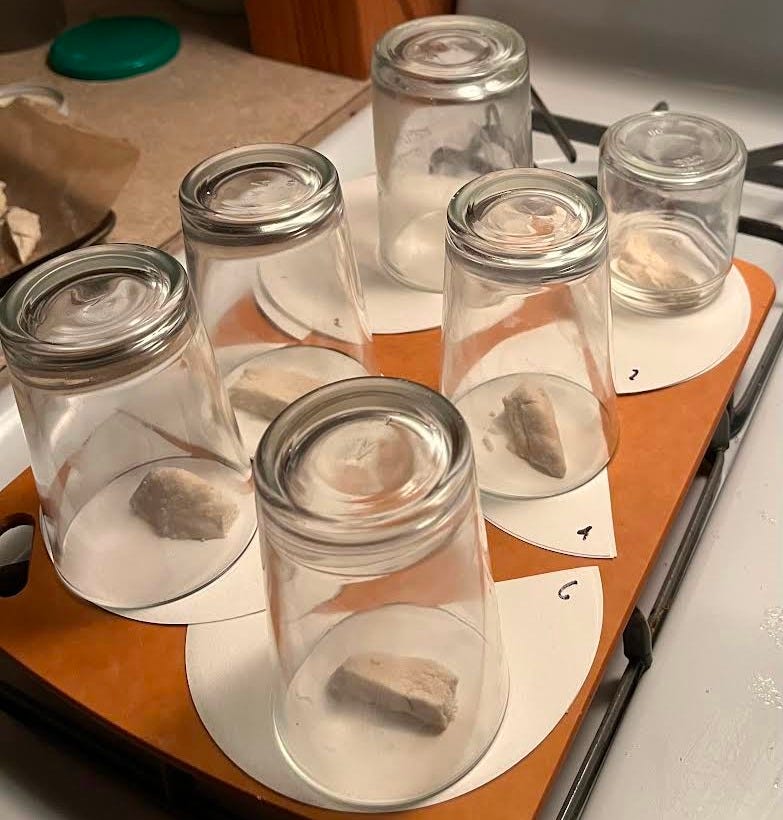

This method, adapted from the manufacturing methodology used in mass production for Middle Eastern and Eastern European markets, relies on highly specific textural and componential conditions of the starting tahini//sesame-solid-lipid matrix being met: specifically, the tahini used for this method must be processed such that it when homogenized, it’s phase is abundantly and consistently fluid—i.e. pourable, unlike most peanut-butter adjacent tahinis sold in the domestic market. I regret that I do not currently have more precise metrics—e.g. flow rate, spherical pascal-miliseconds, zahn cup data, etc. I have, however, identified at least one brand of tahini which consistently yields this desired texture: Dipasa's R&D’s "Biladi Sesame Tahini Paste" (pictured below among other ingredients).

If you have acquired this specific tahini, the following methodology can yield halva with the desired elusive texture.

Ingredients₁:

100 g. Tahini (ideal conditions met)

100 g White Granulated Cane Sugar

55 g H₂O

2 g. NaCl/Salt

(Optional: 5 g. Soapwort (saponaria officinalis) Water-soluble Extract)

this obscure stabilizer—used for centuries in the traditional production of this candy, as well as in most modern mass production processes—will allow for far less precision in the candy steps of this process, and overall expedite the production process, but it is absolutely not required—I have produced several samples with this technique sans-soapwort which have successfully produced the desired texture.

Procedure₁:

Pour tahini into an abundantly large highly-heat-retentive mixing vessel (e.g. stainless steel, glass, iron, etc.) and stir to ensure homogenietiy

Combine sugar, water, salt (and soapwort if available) in a small saucepan—make sure the saucepan will accommodate a thermometer such that it will read accurately (i.e. the liquid has depth enough to do so)

Heat saucepan containing aqueous sugar mixture over medium heat until mixture reaches exactly 248°F

—this is the tempurature you want it to be when it is poured out of the pan; if you take it off the heat at this point, it will likely continue to increase in temperature past the desired mark as it is pours, so perform the following steps with intense deliberation and consideration of carryover heat—I like to turn burner-heat to very low starting at around 240° for the mixture, ensuring the precise temperature is met going into the next step.

Once at 248°F, quickly and gently pour resulting syrup into the prepared tahini vessel.

Incorporate syrup into tahini via a gentle folding motion, working quickly so that the sugar does not set prematurely, but without overmixing or mixing too vigourously as to not accidentally recrystalize the sugar

Remove to a parchmented surface and let set for at least thirty minutes; texture will improve over the following days as it dries ambiently. Once at desired texrture store in airtight container (room temp is fine, but refrigerate if you like cold)

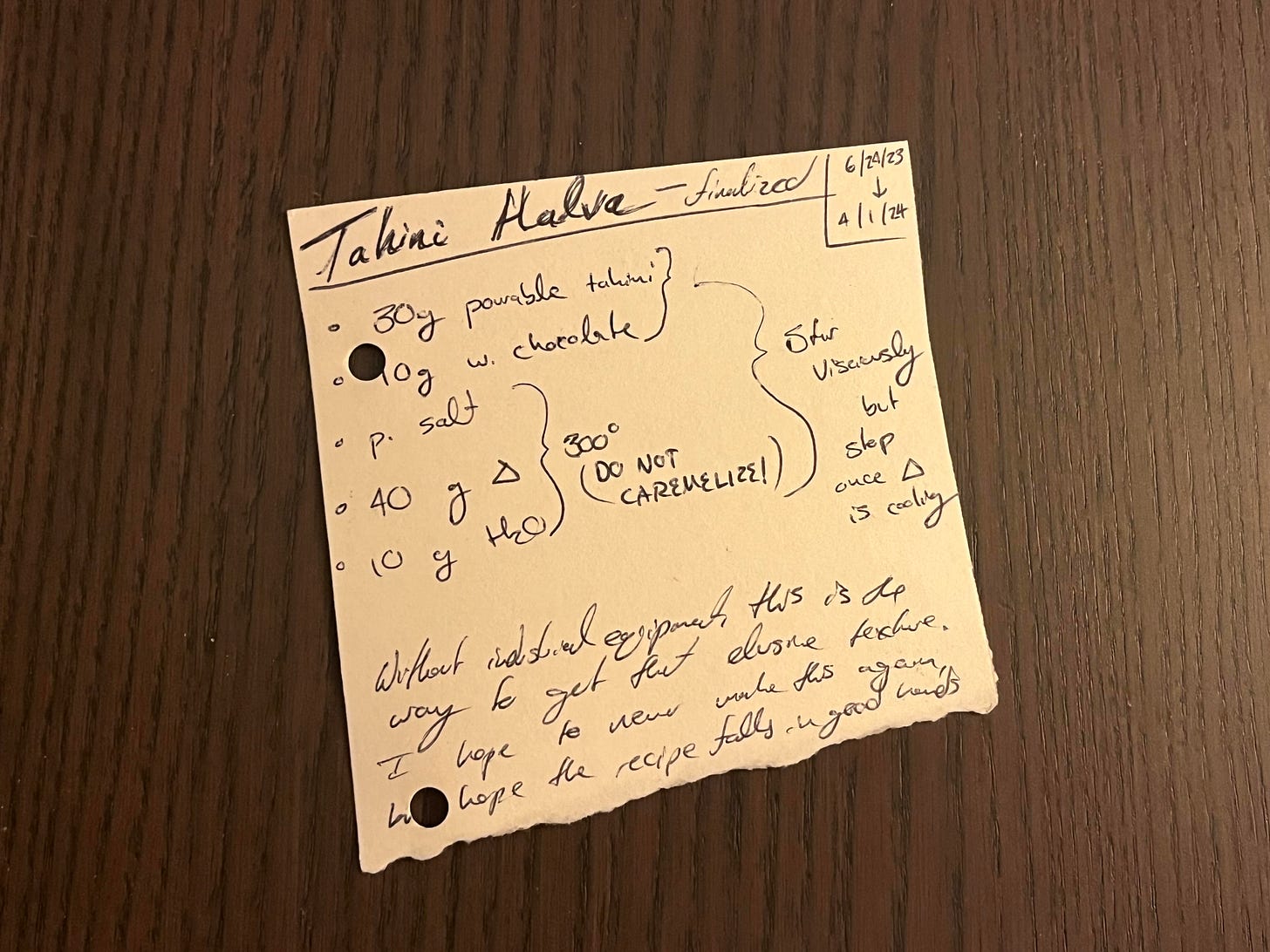

Method 2 — Ideal Tahini Conditions Not Met

If you have not aquirred a tahini adhering to the conditions described in the first section of “Method 1,” a halva with the desired “sandy-yet-soft” texture can be achieved alternatively through the following methodology. I developed this procedure shortly after the original research was conducted in Autumn of 2023 while playing around with Alison Roman’s Tahini Caramel and David Lebovitz’s Caramelized White Chocolate. The technique uses a novel technique of “stabilization” wherein a hard-set candy-ganache acts as the liason between sugar and tahini, sans any real emulsifiers (aside from those present in the white chocolate).

Ingredients₂:

90 g Tahini (any kind!)

30 g white chocolate (chopped or in pieces/morsels)

this does not have to be high quality (e.g. vahlrona ivorie), in fact, I have had more success with this method using lower quality white chocolate (e.g. these).

120 g white granulated sugar

55 g H₂O

2 g. NaCl/Salt

Procedure₂:

Stir tahini in an abundantly large highly-heat-retentive mixing vessel to ensure homogenietiy. Add white chocolate and stir just to distrubute/coat

Combine sugar, water, and salt in a small saucepan—again, making sure the saucepan will accurately accommodate a thermometer

Heat saucepan containing aqueous sugar mixture over medium heat until mixture reaches 300°F

try to pull the mixture as soon as it reaches this temperature to minimize caramelization—which will contribute potentially-undesirable flavors to the final product—if you have some caramelization the method will still work, the flavor just may be impacted

Incorporate final syrup into tahinia (tahini-white-chocolate matrix) via vicious, stirring, ensuring the chocolate is adequately melted, but stopping once the sugar has set to prevent excessively breaking the candy’s continuity

Remove to a parchmented surface and let set for at least ten minutes; texture will improve over the following days as it dries ambiently. Once at desired texrture store in airtight container (again, room temp is fine, but refrigerate if you like cold)

I guess it makes sense that I would promise myself never to delve into this again on April Fools Day, because despite the inscription, I have made this freaking recipe probably at least a dozen more times since April of 2024.

While the recipe (or, pair of recipes rather) is “finalized” (i.e. it consistently produces the candy as desired, enigmatic texture and all), it will never be finished. Once a recipe is “set”—in effect—it only calls out louder to be changed: tweaked, meddled with, reworked, challenged, etc. No matter what I do, I can not and will not find closure with this project. But that’s not a bad thing…

Recipe development is obsession, but I think that’s why I love it. It’s revision and re-revision ad nauseam; consumption in the project until it consumes you—as this one, like so many others, has done to me. But I don’t think that’s necessarily a bad thing… at least for me (I absolutely flourish on obsession; for a long time I considered myself a perfectionist, but I think it would be more accurate to say I’m an obsessionist, really).

Not to mention, it is so very rewarding; at this point, I think I’m probably one of the world’s leading experts on this candy, which I think is pretty cool, even if sometimes I feel like I never want to see the stuff again.

Additional Resources

David Lebovitz's Halvah Recipe (2021)

In this recipe, Lebovitz presents a novel technique for producing this candy using confectioner’s sugar and powdered milk to bypass the more intricate candy steps. The result is an adequately sandy-yet-soft candy that surprisingly almost nails the elusively desirable texture

This would be a good alternative recipe to try if you don’t have success with either of the methods presented above

At-scale Halva Manufacturing Process Videography (Chef Salim Recipes, 2020)

Cool insights into the industrial process in this video and those like it. Also, it demonstrates very well the unreasonability of recreating industrial-scale processes with standard kitchen equipment

Tasting History: Warrior's Halva (Max Miller, 2023)

Although this video focuses on a distinct, non-tahini variety of halva, the methodology of this recipe—lifted from halva recipes of antiquity—is nevertheless fascinating: insightful not only in regards to candy process, but also to the rich anthropolological history of Middle Eastern candies at large.

Wikipedia needs no introduction: it’s the absolute sauce when it comes to secondary sources. For context on the candy, this is a great place to begin. The article, like most Wikipedia pages, provides an extremely broad overview including the history and development of the candy, as well as its diverse variations across different cultures

thanks for reading! :)